Products>

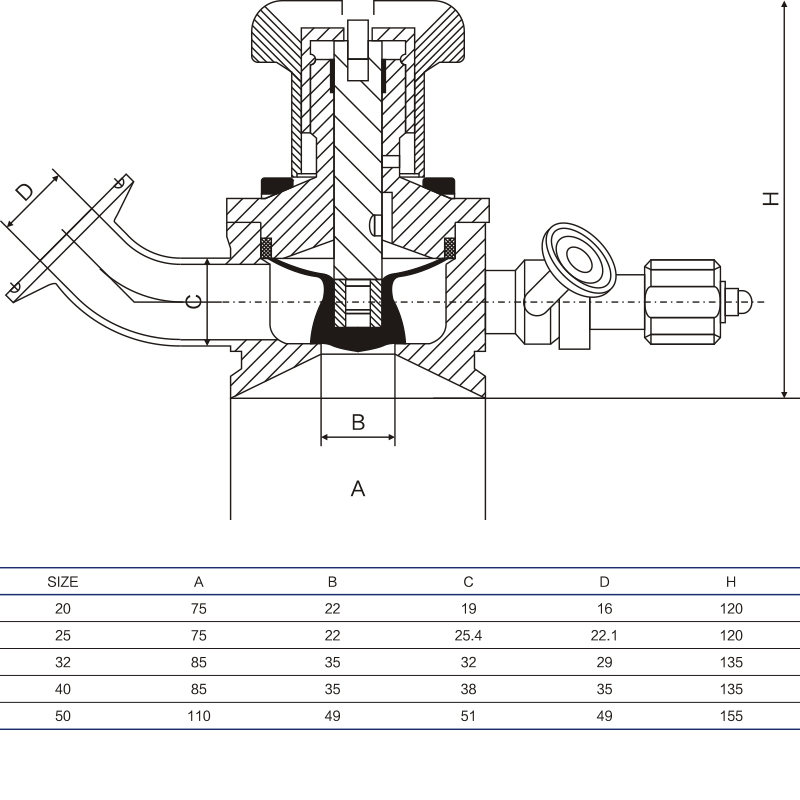

Radial tank bottom diaphragm valve

Characteristics

Sanying valves provide high performance flow control for pharmaceutical and biopharmaceutical fluid handling

system. With hydraulic optimization design, Sanying combines the inherent clarity of a flat diaphragm valve.

The best features of washability and embolic valves, this combination of features ensures that Sanying provides

A unique combination of low flow resistance and proven hygienic design. Sanying structure is sturdy and consists of

Made of durable materials to ensure a long service life under the required operating conditions.

Hygienic design for biopharmaceutical applications

Sanying has a unique patented design that uses a clamp to secure the valve diaphragm in the valve body and drive

The structure between the moving heads. The moving body of all drive heads is isolated from the liquid being treated, and

Most sizes of valves do not require tool removal or maintenance. Valve cavity and pipe connection are none

The blind segment is self-discharged. Compared with traditional flat-diaphragm valves, using Sanying in a series

The amount of valves in the system can be reduced by up to 30%. This can result in liquid residue in the entire piping system.

Reduction.

Sanying valves provide high performance flow control for pharmaceutical and biopharmaceutical fluid handling

system. With hydraulic optimization design, Sanying combines the inherent clarity of a flat diaphragm valve.

The best features of washability and embolic valves, this combination of features ensures that Sanying provides

A unique combination of low flow resistance and proven hygienic design. Sanying structure is sturdy and consists of

Made of durable materials to ensure a long service life under the required operating conditions.

Hygienic design for biopharmaceutical applications

Sanying has a unique patented design that uses a clamp to secure the valve diaphragm in the valve body and drive

The structure between the moving heads. The moving body of all drive heads is isolated from the liquid being treated, and

Most sizes of valves do not require tool removal or maintenance. Valve cavity and pipe connection are none

The blind segment is self-discharged. Compared with traditional flat-diaphragm valves, using Sanying in a series

The amount of valves in the system can be reduced by up to 30%. This can result in liquid residue in the entire piping system.

Reduction.