Products>

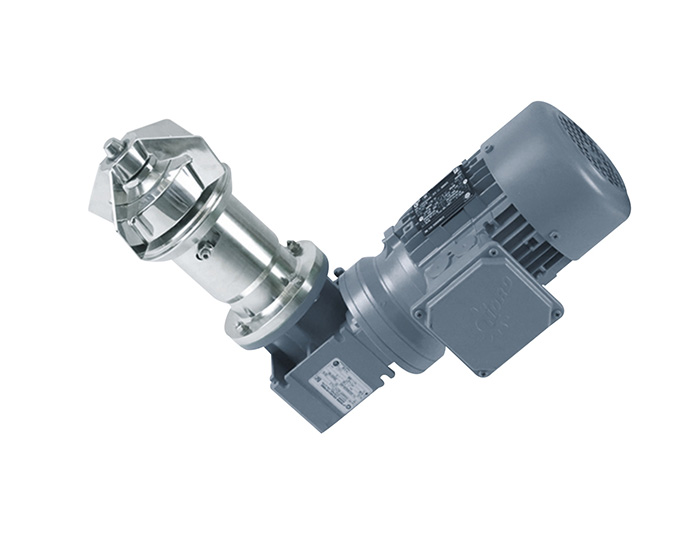

Magnetic stirrer

A magnetic stirrer is a stirrer installed at the bottom of a container and driven by magnetic force. It adopts a fully enclosed, leak free, and pollution-free mixing method. Due to its magnetic transmission, it transmits torque in a non-contact manner without a transmission shaft. It replaces the dynamic seal of the transmission shaft with a static seal using an isolation sleeve, completely solving the leakage problem that mechanical seals cannot solve. This equipment is mainly used for dissolution, mixing, and ingredient preparation in industries such as pharmaceuticals and food.

Tank volume: 10L -10000L

Link method: Welding

Use upper speed limit min/r: S00

Maximum Work Assistance (MPa): 0.3

Working limit SJTC: 220

Applicable viscosity upper limit CP: 100

Equipped with frequency converter: Yes

Impeller form: 4-piece type

Reducer: 0.18kw-S.Skw/380V/S0Hz

Motor brand: SWE/Nord

Installation method: vertical/horizontal

Contact material material: 316L

Non contact material: 304

Bearing material: Silicon carbide seal, completely solving the leakage problem that mechanical seals cannot solve.

This device is mainly used in industries such as pharmaceuticals and food

Scope of application: Various stainless steel reaction tanks, mixing tanks, storage tanks and other mixing devices.

Operating conditions: Flammable, explosive, leak prone, and require high sealing conditions.

Working temperature: -40-150 ° C

Product material: 316L or 304

Working pressure: 0-0.3Mpa

Selection instructions: It is necessary to understand the viscosity and density of the medium, working temperature, and working pressure.

Link method: Welding

Use upper speed limit min/r: S00

Maximum Work Assistance (MPa): 0.3

Working limit SJTC: 220

Applicable viscosity upper limit CP: 100

Equipped with frequency converter: Yes

Impeller form: 4-piece type

Reducer: 0.18kw-S.Skw/380V/S0Hz

Motor brand: SWE/Nord

Installation method: vertical/horizontal

Contact material material: 316L

Non contact material: 304

Bearing material: Silicon carbide seal, completely solving the leakage problem that mechanical seals cannot solve.

This device is mainly used in industries such as pharmaceuticals and food

Scope of application: Various stainless steel reaction tanks, mixing tanks, storage tanks and other mixing devices.

Operating conditions: Flammable, explosive, leak prone, and require high sealing conditions.

Working temperature: -40-150 ° C

Product material: 316L or 304

Working pressure: 0-0.3Mpa

Selection instructions: It is necessary to understand the viscosity and density of the medium, working temperature, and working pressure.